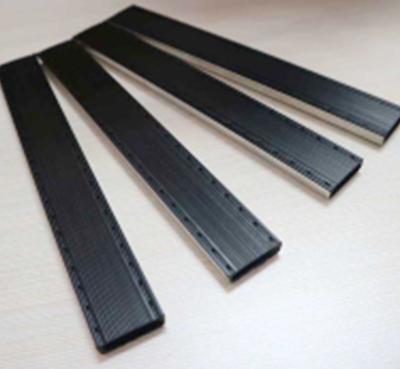

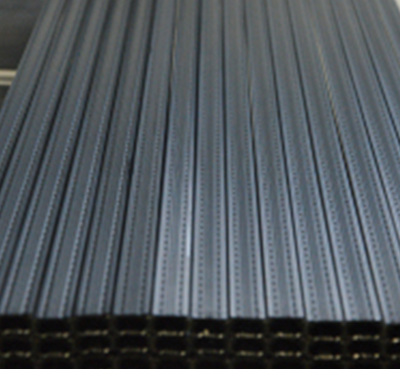

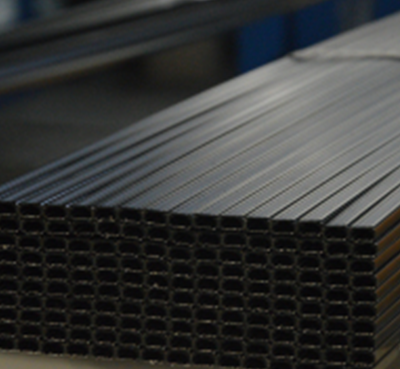

The warm-edge is a kind of material used between insulating glass. It is processed through the process of cold and hot co-extrusion. It is a material used to achieve the function of heat preservation and noise reduction. The cavity is composed of aluminum or aluminum alloy material, which is used to fill the desiccant, isolate the original insulating glass sheet, and play a supporting structural product. Excellent bending performance, can meet any bending angle requirements in the production process.

Comparison of warm edge strips and aluminum spacer bar strips:

1: Warm edge technology reduces the heat transfer coefficient of the entire window, which is an effective way to improve the thermal performance of the entire window.

2: Warm edge technology can greatly increase the edge temperature of the insulating glass and improve its anti-condensation performance.

3: It can effectively reduce the possibility of glass spontaneous explosion and thermal explosion caused by the temperature difference of the glass during use.

4: Warm edges can cause glass to form broken bridges.

Supporting product specifications:

4mm, 5mm, 5.5mm, 6mm, 6.5mm, 7mm, 8mm, 8.5mm, 9mm, 10mm, 11mm, 11.5mm, 12mm, 14mm, 14.5mm, 15mm, 16mm, 17mm, 18mm, 19mm, 20mm , 21mm, 25mm and other specifications of aluminum bars, can also be customized according to the special needs of users.

Model: 4A, 5A, 6A, 7A, 8A, 9A, 10A, 11A, 12A, 14A, 15A, 16A, 17A, 18A, 19A, 20A, 21A. 25A.

1-1407 Meilin Mansion Wuyingshan Middle Road Tianqiao district Jinan city Shandong province China

Phone number:+8618660431138/18663713068

Email:weili001@weiliglass.com;weili009@weiliglass.com

鲁公网安备 37010502001894号

鲁公网安备 37010502001894号