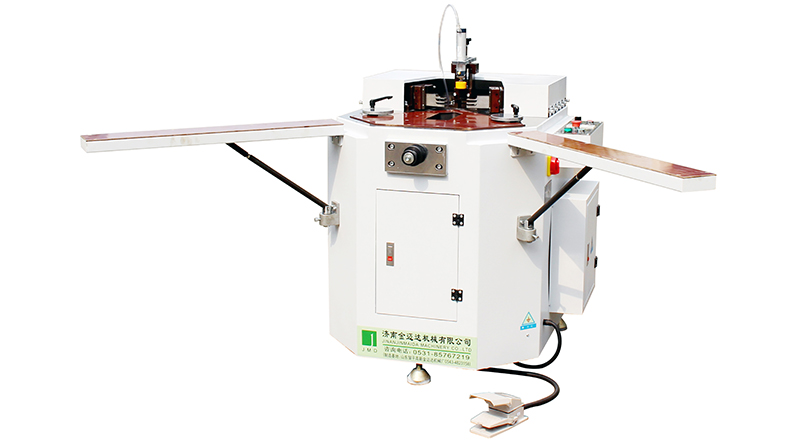

This machine is one of the necessary equipment for the production of high-grade aluminum alloy doors and windows. It is mainly used for the extrusion connection of 90° joints of side-hung doors and windows with corner structure.

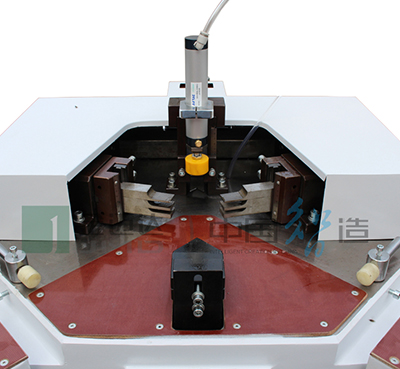

Before forming the corner, put a common corner code in the two connected profile cavities. After the positioning is tightened, the two hydraulically driven punches forcefully rush to the groove of the corner code, causing permanent cold deformation of the outer wall of the profile.

The internal positioning device can be raised and lowered, which is suitable for making large-size doors and windows.

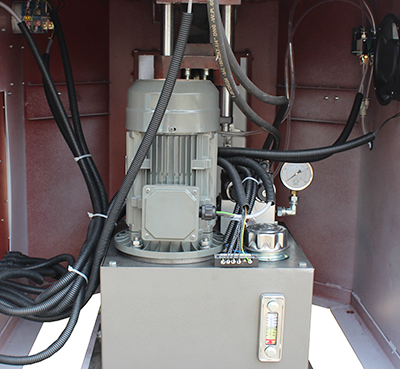

Power specification: three-phase four-wire 380V/50Hz

Motor power: 2.2kW

Motor speed: 1400r/min

Working pressure: 0.5~0.8MPa

Air consumption: 2L/min

Oil pump pressure: maximum 10MPa

Rated oil pressure: 10MPa

Maximum height of processed profile: 100mm

Fuel tank capacity: 175L

Group angle cylinder stroke 35mm

Positioning cylinder stroke 72mm

Dimensions: 1300x1300x1300mm

Total weight of the whole machine: about 450kg

1-1407 Meilin Mansion Wuyingshan Middle Road Tianqiao district Jinan city Shandong province China

Phone number:+8618660431138/18663713068

Email:weili001@weiliglass.com;weili009@weiliglass.com

鲁公网安备 37010502001894号

鲁公网安备 37010502001894号