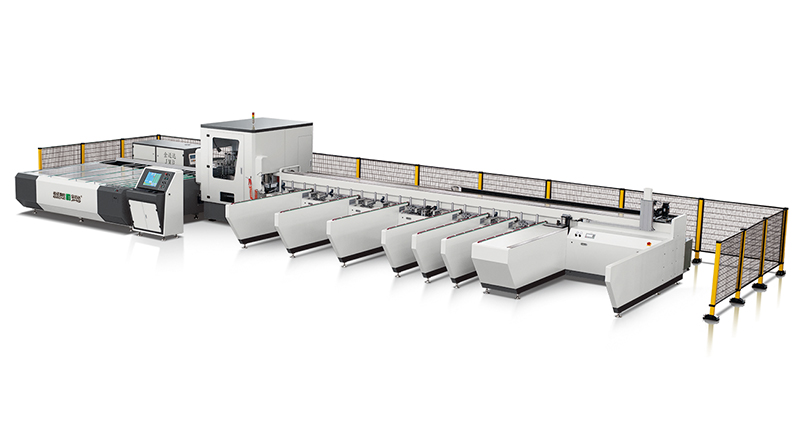

1. This sawing processing center is the fourth generation of our company. On the basis of the previous three generations, it combines advanced foreign design concepts and ideas, a brand-new industrial sheet metal design, and is made after rigorous demonstration and careful design. A new generation of profile cutting equipment with the highest production efficiency and the most obvious profile saving effect on the market.

2. The left and right saw blades are fixed at 45°, abandoning the traditional 90° or arbitrary angle cutting, focusing on double-end 45° cutting of broken bridge aluminum door and window profiles and all-aluminum household profiles. Makes a new generation of sawing machining centers have a substantial improvement in cutting efficiency and material saving. Moreover, the equipment structure is simpler and easy to operate.

3. The feeding part and the discharging part also adopt new design ideas, and use industrial assembly line profiles as the frame, making the appearance of the equipment simple and atmospheric.

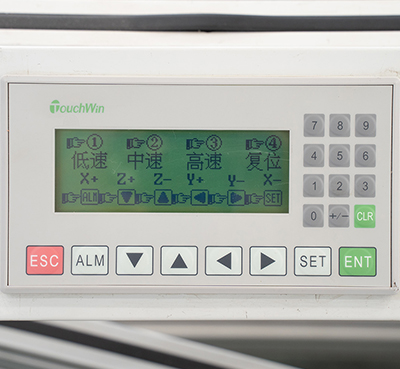

4. This equipment adopts Schneider numerical control system and is equipped with an industrial control computer (industrial control computer), which makes the equipment run more stably in the harsher production environment for a long time.

5. The position adjustment of the manipulator adopts full numerical control. The manual pulse generator is used to adjust the position of the manipulator. The system will remember the position. When cutting the same specification profile again, the system will call the saved position data of the manipulator, reducing the operation errors of workers and improving work efficiency. .

6. The feeding frame adopts a brand-new structural design, is welded with high-quality steel, and is artificially aging, so it will not be deformed after long-term use. Makes the robot's feeding accuracy higher, more stable and faster.

7. This equipment can realize cutting without material head. Because the traditional double-head saw cutting material is manual feeding, the material head length must be set aside 5~10mm, which is easier for workers to operate. However, the use of CNC feeding completely avoids the waste of profiles caused by human factors, and cutting each profile can save 5-10mm. About 1% of materials can be saved by calculation.

8. The cutting time of each piece of this equipment is about 10~13 seconds (average number). According to 8 hours/shift, it can cut 2,200 2600 pieces, which is 2-3 times the efficiency of a double-head saw.

10.The industry's unique isolation transformer device eliminates the instability of external voltage and makes the equipment run smoothly.

Power specification: three-phase four-wire 380V/50Hz

Total power: about 12.7kW (including dust collection equipment 3.7kW)

Working pressure: 0.5~0.8MPa

Saw blade spindle motor: 2.2kW 3000r/min

Air consumption: 120L/min

Saw blade specifications: φ500x4.0x3.4x30x120T

Cutting angle: dual head fixed 45°

Sawing length range: 150~6500mm

Sawing width: 125mm

Cutting height: 150mm

Feeding speed: 0~ 70m/min

Discharge speed: 0~70m/min

Cutting motor speed: 2860r/min

Saw blade cutting speed: 0~15m/min stepless adjustable (manual)

Profile cutting speed: about 10~13 seconds/piece (average speed)

Lubrication, cooling: automatic lubrication, automatic spray cooling tool

Dimensions: 13200x3800x2100mm

Total weight of the whole machine: about 5000kg

1-1407 Meilin Mansion Wuyingshan Middle Road Tianqiao district Jinan city Shandong province China

Phone number:+8618660431138/18663713068

Email:weili001@weiliglass.com;weili009@weiliglass.com

鲁公网安备 37010502001894号

鲁公网安备 37010502001894号