The glue machine is a manual two-component glue machine (air motor type), which is used for the final sealing of insulating glass production.

Model: ST06

Production : 30-40 days

ST06 type two-component glue dispenser (air motor type)

The system adopts the best domestic and foreign technology and craftsmanship. The key components (main motor, auxiliary motor, pressure relief valve, back pressure valve, mixing core and glue gun, etc.) are produced by famous foreign companies to ensure reliable operation. The system is mainly composed of air motor, main material pump, proportioning pump, pressure plate, feeding pump, glue gun, agitator, proportional detection station and other devices.

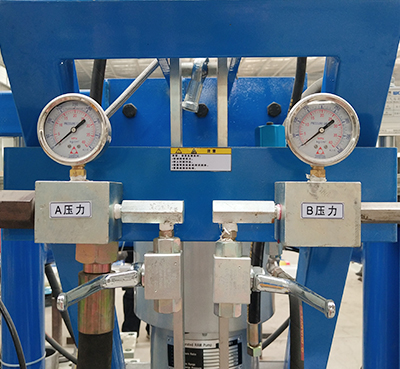

Base material supply system and curing agent supply system

Using a special high-pressure plunger pump, two-way equal feeding, with a pressurized feeding pressure plate, fully ensure the full cavity pumping of high-viscosity fluid, prevent air mixing, and ensure stable output medium flow. Pneumatic lifting mechanism makes it easy and quick to change materials.

Proportioning system

Adopt an adjustable booster synchronous linkage ratio mechanism. To adapt to the requirements of the ratio of different materials (6:1-14:1), there is a special ratio detection mechanism, the adjustment of the ratio is very convenient, and the accuracy of the ratio is less than ±2%. ...

Mixer

Use the internationally popular static reciprocating tube mixer. Small size and light weight. The imported mixing core makes the mixing more uniform, reliable and durable. The unique needle-shaped one-way valve in China ensures that the mixture does not flow back and avoids solidification in the tube.

Glue system

Imported glue gun is used, and the operation is extremely simple. After the gas pressure is adjusted for the first time, almost no operation is carried out. Glue supply, proportioning, mixing and spraying are combined into one, and only need to be gently squeezed (released) each time Trigger the spray gun, and the whole system can be started (closed) immediately. Sensitive high-pressure protection valve (import) makes operation and use safer. ...

The parts in contact with the fluid are all made of high-quality stainless steel. The sealing ring uses imported high-quality Teflon material, which is reliable and durable. Perfect and thoughtful service and random parts supply, so that you can use it without worry.

...

Applicable glue types:

silicone structural glue, polysulfide glue, and most other two-component glues. Special requirements can be customized according to user needs.

Main technical parameters

(20℃ value with heavy oil as medium. Different viscosity media have different parameters at different temperatures):

Air source pressure:0.5___0.8Mpa

The highest working frequency of the main pump:60 times/min

Maximum working pressure of fluid:34.5Mpa

Base material supply:55Gal (200L) standard barrel

Working pressure: 20.0Mpa

Curing agent supply: 5Gal (20L) standard barrel

Maximum output flow:10L/min

Maximum air consumption: 0.8 cubic meters/min

Glue gas pressure ratio:50:1

The weight of the complete system:600kg

Proportion range:6:1__14:1

The overall dimensions of the mainframe:1100×950×1630(2260)

1-1407 Meilin Mansion Wuyingshan Middle Road Tianqiao district Jinan city Shandong province China

Phone number:+8618660431138/18663713068

Email:weili001@weiliglass.com;weili009@weiliglass.com

鲁公网安备 37010502001894号

鲁公网安备 37010502001894号