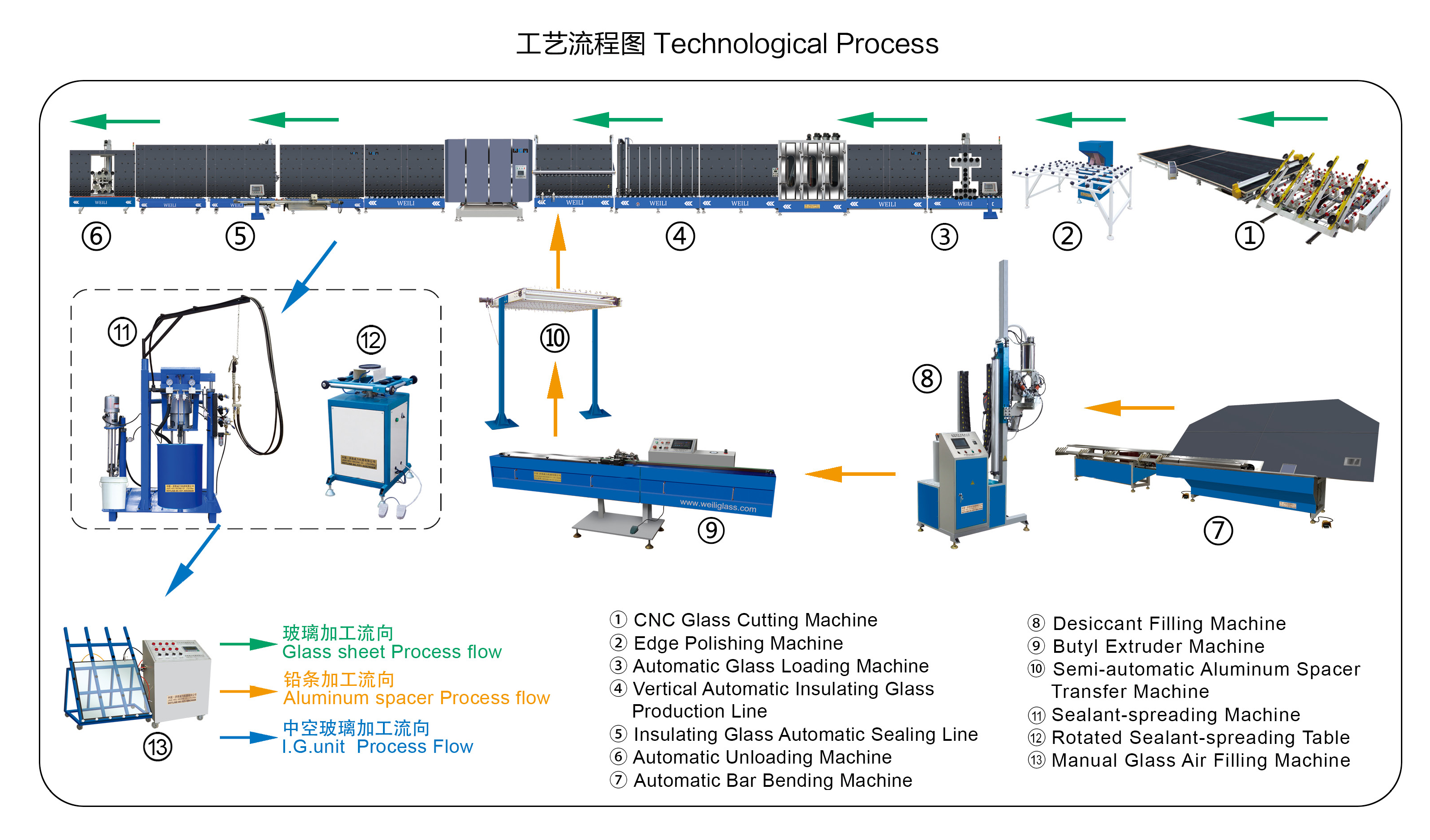

This machine is an automatic butyl rubber coating machine, which is used for the first sealing in the production of insulating glass. .

Model; WL2000/WL3000

Production : 30-40 days

Highlights:

1. It adopts double-engine oil cylinder, equipped with a large-volume glue cylinder, which can load 14L butyl rubber at one time (2 normal ¢180mm butyl rubber).

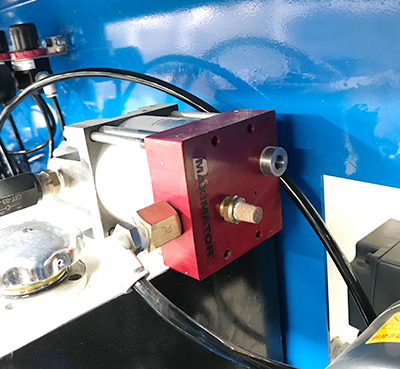

2. The main pump of the booster system adopts the booster pump imported from Germany by MAXIMATOK

Main performance characteristics:

1. This machine is a semi-automatic coating machine (that is, the spacer frame is manually supported for side-by-side operation), with frequency conversion speed regulation.

2. Put the spacer frame on the conveyor belt and manually support the frame conveyor belt to run. When passing the sensor, the conveying roller and the glue valve will automatically act according to the set program.

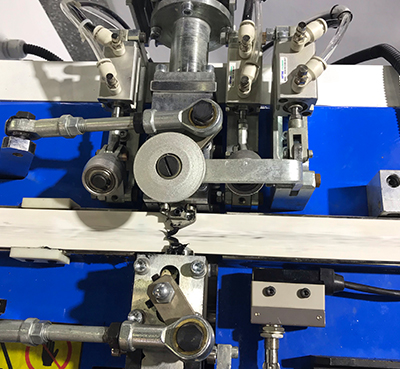

3. The swing cylinder moves, the pressing wheel is pressed down, and the aluminum spacer frame is pressed to advance. When the spacer frame reaches the glue head, glue is applied, and the glue is evenly coated on the aluminum spacer frame.

4. When the other side of the equal interval frame is about to reach the pressure roller, the pressure roller will lift up and when it leaves the glue head, the glue valve will automatically close and stop glue dispensing. The above program is controlled by PC, time is controlled by man-machine interface, and can be adjusted by touch.

5. In terms of design, selection of vitality parts and gluing effect, it is at the leading level in China.

6. Using PLC control system, positioning, conveying and gluing are all completed automatically.

7. The conveying adopts frequency-conversion speed-regulating motor speed regulation, and the running speed is stable.

8. There is an automatic positioning mechanism without pressure release to fully ensure that the gap between the glue head and the two sides of the bulkhead is evenly coated.

The main technical parameters:

Squeeze pressure :12-14Mpa

Power supply :380V

Gluing temperature: 100-140 degrees Celsius

Total power: 2.5Kw

Pneumatic pressure: 0.5-0.8Mpa

Adjustable range of rubber head: 4-20mm

Gluing speed: 22 meters/minute

Dimension: 3000*700*1236mm

Total weight: 850kg

Main components:

|

Serial number |

Product name |

Brand name |

Brand location |

|

1 |

Control part PLC |

Omron |

Japan |

|

2 |

Color touch screen |

Kinco |

Taiwan |

|

3 |

Photoelectric switch |

Omron |

Japan |

|

4 |

Frequency converter |

Schneider |

France |

|

5 |

Temperature table |

Omron |

Japan |

|

6 |

The electromagnetic valve |

AirTAC |

Taiwan |

|

7 |

Low-voltage electrical appliances |

Schneider |

France |

|

8 |

cylinder |

AirTAC |

Taiwan |

|

9 |

Glue nozzle adjustment cylinder |

SMC |

Japan |

1-1407 Meilin Mansion Wuyingshan Middle Road Tianqiao district Jinan city Shandong province China

Phone number:+8618660431138/18663713068

Email:weili001@weiliglass.com;weili009@weiliglass.com

鲁公网安备 37010502001894号

鲁公网安备 37010502001894号